Achievement unlocked…Solar Power

It’s over a year since I purchased all the ingredients for our solar install. It’s one of those projects that fell to the sidelines for while but I got back on track. Over the past few days I’ve been running wire and getting up the courage to tape (yes tape) the panels onto the roof. I’m getting close to finished, the last major effort will be to tape on some wire tie downs, I’m pretty sure those would be a good thing to have.

It’s over a year since I purchased all the ingredients for our solar install. It’s one of those projects that fell to the sidelines for while but I got back on track. Over the past few days I’ve been running wire and getting up the courage to tape (yes tape) the panels onto the roof. I’m getting close to finished, the last major effort will be to tape on some wire tie downs, I’m pretty sure those would be a good thing to have.

So first things first, the technology rundown. I’ve gone against the prevailing winds and am using flexible solar panels and a Chinese manufactured MPPT solar controller.

Solar Panels

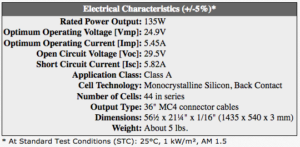

The solar panels are a no name brand purchased from Discount Solar in California. They are rated at 135 watts and 24 volts. This gives the MPPT controller lots of extra voltage to play with as it adjusts the incoming power. I got four of these panels, and have currently placed three on the roof. This gives me 405 watts on the roof with another 135 in reserve. The fourth I intend to keep for winter use when I’d like to be able to have a panel better positioned for the sun. Early on I tested one of the panels on the ground, angled for the best sunlight. I actually saw almost 24 volts at 6 amps going into the controller.

The solar panels are a no name brand purchased from Discount Solar in California. They are rated at 135 watts and 24 volts. This gives the MPPT controller lots of extra voltage to play with as it adjusts the incoming power. I got four of these panels, and have currently placed three on the roof. This gives me 405 watts on the roof with another 135 in reserve. The fourth I intend to keep for winter use when I’d like to be able to have a panel better positioned for the sun. Early on I tested one of the panels on the ground, angled for the best sunlight. I actually saw almost 24 volts at 6 amps going into the controller.

My original plan was to place all four on the roof, with two serial/two parallel. That would have provided roughly a max 48 volts at 11 amps. The higher voltage would reduce voltage loss over the 10 gauge wiring I used from around 3% to around 1%. It’s still a consideration, but the placement for the fourth panel is not ideal. It would have to lay under the antenna which would lay directly on the panel when it is down. I expect that would scuff up the surface and reduce the panel output a bit, but it may also be more convenient. The panel would also overlap onto the end cap by about 2 inches. Not a disaster, but not desirable either.

MPPT Solar Charge Controller

The controller is a Tracer 4215 BN MPPT controller. It’s highly programmable so I’m able to modify the parameters to work well with my lithium batteries. It’s got a huge heat sink, but I have yet to feel it even get warm. There’s not much to say about this thing. It’s programmable and the firmware can be updated. I don’t think it’s particularly great, but the construction seems good and the conversion loss seems incredibly small.

The controller is a Tracer 4215 BN MPPT controller. It’s highly programmable so I’m able to modify the parameters to work well with my lithium batteries. It’s got a huge heat sink, but I have yet to feel it even get warm. There’s not much to say about this thing. It’s programmable and the firmware can be updated. I don’t think it’s particularly great, but the construction seems good and the conversion loss seems incredibly small.

Lithium Batteries

At some point I’ll write up a post about the batteries, but for inquiring minds: We have 300ah of LiFEPO4 batteries attached to a BMS that monitors voltage, temperature and state of charge (SOC). It also has cell balancing but I expect I’ll never charge at a high enough voltage for that to kick in (I have older circuitry that needs to reach 3.7 volts in a single cell before balancing kicks in). You can find out more about my batteries at Elite Power Solutions. My interim shore power charger is a Boondocker with adjustable voltage. It doesn’t work great and I’m considering moving over to a Magnum Inverter/Charger I just happen to have laying around in a fresh box, but that’s for another day.

How it was done

I attached the three panels using 3M VHB tape, a combination of 4941 and 4950. I thought I had enough to mount four panels, but my paranoia got the better of me and I used all that on three panels, with hopefully enough 4950 left for the wire tie downs. I then used Sika Flex 221 white to cover the screw holes and and edges of the panel. That should prevent water getting underneath and to the tape as well as add a touch more adhesion. This was my first use of a caulking gun with sealant, and the first panel was quite a mess. Fortunately I avoided getting any on the cells. The other two panels I used painters tape along the edges to better control the Sika Flex and those panels look much better, almost like I know what I’m doing.

I first used a scratch pad to abrade the back surface of the panels, cleaned the surface, and used a J-Roller to put on the tape. Then a deep clean with soapy water for the roof, rinse, then used mineral spirits to really clean it. Placed the panels, used the J-Roller again to get the tape to adhere, and presto, panels I couldn’t pull off by hand. Others have traveled tens of thousands of miles with panels attached this way, here’s to hoping I did things well enough that they stay on. I’m sure the extra tape I used will ensure the remain.

The sun will come out Tomorrow

Vancouver has had a particularly dismal summer so far, rain and clouds have dominated. Even so, I’ve had pretty good results with the solar panels. I’m typically getting 5-15 amps with the clouds. In spots of sunlight I’ve seen as high as 25 amps at 14 volts (after mppt conversion). In high sun/full sun the panels are delivering 80-90% of the rated capacity. I don’t expect to ever see over 90%, and I expect the output from the panels to degrade over time. We’re also recouping all the battery use and then some. Its fun to watch the battery charge while still using everything (yes I need to get out more).

Vancouver has had a particularly dismal summer so far, rain and clouds have dominated. Even so, I’ve had pretty good results with the solar panels. I’m typically getting 5-15 amps with the clouds. In spots of sunlight I’ve seen as high as 25 amps at 14 volts (after mppt conversion). In high sun/full sun the panels are delivering 80-90% of the rated capacity. I don’t expect to ever see over 90%, and I expect the output from the panels to degrade over time. We’re also recouping all the battery use and then some. Its fun to watch the battery charge while still using everything (yes I need to get out more).

Prior to placing the panels, I ran off the batteries for a couple days. Since we’re still on hookups, the fridge and one laptop charger is running on 120 volt. Everything else, including our TV, runs on 12 volt. We used 18% of the battery in the last 24 hours, or about 55ah (actually more since solar was contributing during the day). That will go up when we’re fully disconnected. So far today, we’ve recovered 20% of the battery (60ah) and I expect to get another 4-5%. That’s on a day that was cloudy a good chunk of the time. Of course we can minimize energy usage by being a little more conservative. It’s great to see that our 300ah of lithium batteries give us plenty of buffer, as well that we would have been skating on thin ice with the original batteries.

“Free” as in Sunlight!

But there is no free lunch. My panels cost a premium compared to standard glass panels, closing in on twice as much. Contrary to often sited reasons, I didn’t go with flex panels for appearance (I actually kind of like the look of glass panels on newer Airstreams), aerodynamics or to try the latest gadget, I went with them for weight. After install, regular glass panels would probably weigh in at 4-5X what the flex panels weigh. Each of my panels weigh about 5 lbs, a single 100W panel typically weighs 20lbs. With my 540 watts the weight is less than 20lbs vs 120lbs to match with glass panels. We don’t travel light, so every pound counts.

But there is no free lunch. My panels cost a premium compared to standard glass panels, closing in on twice as much. Contrary to often sited reasons, I didn’t go with flex panels for appearance (I actually kind of like the look of glass panels on newer Airstreams), aerodynamics or to try the latest gadget, I went with them for weight. After install, regular glass panels would probably weigh in at 4-5X what the flex panels weigh. Each of my panels weigh about 5 lbs, a single 100W panel typically weighs 20lbs. With my 540 watts the weight is less than 20lbs vs 120lbs to match with glass panels. We don’t travel light, so every pound counts.

Standing on the shoulders of giants

While I have some electrical and electronics background, I have to acknowledge the many people who’s experience and knowledge were the basis of my DIY solar project. Technomadia for getting me thinking about lithium; The Wynns for getting me thinking about flexible solar panels; Multiple other full timers blogging their projects and experiences; Lewster and many many others on airforums.com. Thank you all for sharing your insights and knowledge with everyone.